About us

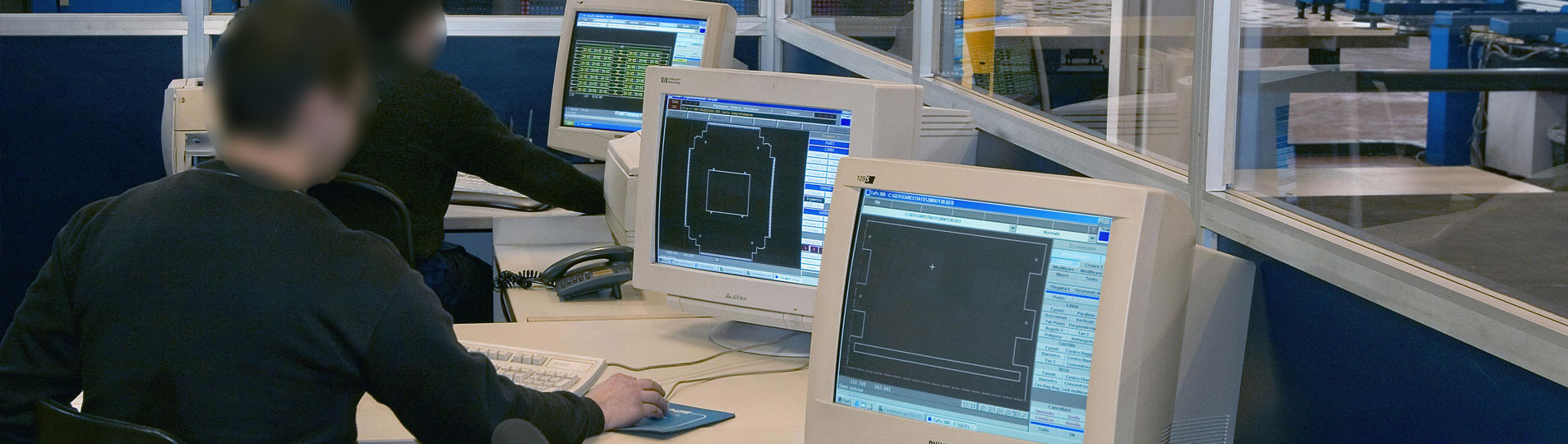

Thanks to the experience accrued throughout the years, to the investments in state-of-the-art machinery and to the continuous research aimed at meeting the requirements of an increasingly demanding market, we have developed a wide range of products ensuring our clients – through our processes – high quality, efficiency and competitiveness.

Thanks to the experience accrued throughout the years, to the investments in state-of-the-art machinery and to the continuous research aimed at meeting the requirements of an increasingly demanding market, we have developed a wide range of products ensuring our clients – through our processes – high quality, efficiency and competitiveness.Where We Are

The Processes

Cutting is usually the first operation to be performed when a part is manufactured.

is usually the first operation to be performed when a part is manufactured.

Our punching workshop utilizes punching machines of the TRUMPF brand, a leading company in the machine tool industry, in order to ensure high quality, fast and safe processes for both single parts and flow productions.

is usually the first operation to be performed when a part is manufactured.

is usually the first operation to be performed when a part is manufactured.Our punching workshop utilizes punching machines of the TRUMPF brand, a leading company in the machine tool industry, in order to ensure high quality, fast and safe processes for both single parts and flow productions.

Laser cutting is the innovative revolutionary sheet metal cutting technique, versus punching.

Laser cutting is the innovative revolutionary sheet metal cutting technique, versus punching.Thanks to the high versatility of the state-of-the art CNC laser cutting systems, the most diversified geometrical shapes can be cut on pickled and galvanized sheet metal, stainless steel and aluminum, even if of large thickness.

After the finishing treatments (painting or galvanizing, if required), the parts that have been manufactured through the aforementioned processes are transferred to the fitting workshop/warehouse.

After the finishing treatments (painting or galvanizing, if required), the parts that have been manufactured through the aforementioned processes are transferred to the fitting workshop/warehouse.Elifra uses a 1,500 sq.m building to check, assemble and store – if required – the products until shipment.